The Most Technologically Advanced Products in the Industry

Ultraflote's state-of-the-art covers are constructed of the highest-quality materials available, and can be customized by our experienced, talented engineers to make sure they conform to your project's unique needs. We've installed over 15,000 projects at sites around the world, tailored for anything and everything.

Over 50 Billion Pounds Saved

Aluminum floating roofs offer a lightweight, high-strength, corrosion-resistant, fire-safe solution to preventing evaporation that would otherwise lead to product loss and environmental damage. Ultraflote’s industry-defining design reduces the creation of static discharge and keeps your oil & gas and industrial liquids protected.

Our products can be fully customized to meet client needs and we’re available to work on projects big and small, no matter where in the world they may be. Our staff will take care of anything and everything you may require of us.

Contact us for more information

Ultraflote aluminum pontoon floating roofs are constructed of only the highest marine grade material to maximize strength and flexibility and minimize the risk of corrosion. We provide coverage solutions that last – and all the services necessary to install, maintain and repair them as well. Our expert team of engineers possess the skills to customize a floating roof to conform to your unique size and product specifications and test your roof to ensure it can handle real-world conditions.

In addition, Ultraflote will supply your operation with the supervisors and construction staff required to assemble and install your purchase. Although we design and build all of our products to last and withstand extreme operating conditions, we are always available for maintenance and repairs. We’ll even conduct inspections to make sure your equipment is up to code.

This is why Ultraflote has become the trusted name in providing aluminum internal floating covers for petroleum and petrochemical tanks around the world. We are an industry-defining leader because of the expertise and quality underlining every product and service we offer.

Ultraflote internal floating covers prevent evaporation of volatile petroleum liquids and can pay for themselves in less than six months. When storing gasoline, a standard, fixed roof tank of 120 feet (36.7 meter) in diameter can lose $750,000 worth of valuable product annually, and cause 1.3 million pounds of pollution. By preventing in excess of 98% of these vapor losses, our covers pay for themselves in a very short period of time.

Ultraflote’s aluminum internal floating roofs provide the most cost-efficient, effective solution to preserving your assets. They float on the liquid surface, prevent evaporative loss of the product, and protect against external contamination. Because of their modular, all-bolted construction, our covers install quickly, minimizing down time.

Quality aluminum floating roofs reduce costs while maximizing safety and profitability. The major benefits of the Ultraflote Cover are threefold:

Reducing Pollution

A standard 120 foot tank with no floating roof emits over 1.3 million pounds of pollutants annually. Our roofs can prevent in excess of 99% of these vapors from entering the atmosphere. Ultraflote is actively involved with the American Petroleum Institute’s Committee on Evaporation Loss Measurement and has set the standard for industry regulation. Please read “Evaporative Loss from Floating Roof Tanks” in the API Manual of Petroleum Measurement Standards, Chapter 19, Section 2 for more about our contributions to pollution reduction.

Saving Money

Without protection, a standard 120 foot tank storing gasoline typically loses more than 6,000 barrels of product a year. Ultraflote covers prevent the evaporation of 5,900 barrels within the same span of time and often pay for themselves after the first six months of use. Let us compute how much the Ultraflote Internal Floating Roof can save for you by completing the Economic Evaluation Form.

Because our aluminum floating roofs are compact enough to be installed through existing manholes, you also save time and resources by not having to cut and replace doorsheets in your shell.

Promoting Safety

Safety is one of the most important reasons to opt for an Ultraflote internal floating roof. Depending on the product, a tank with a fixed roof can trap vapors that are in the explosive range, making the entire structure vulnerable to fires, explosions and other disasters. Our roofs are designed to trap a layer of saturated vapors that are well above the explosive range, therefore ensuring they remain as safe as the liquid itself. This keeps the space above our cover vapor-free, greatly reducing the risk of an incident.

Ultraflote’s engineering team constantly explores and refines our aluminum petroleum roof products to ensure quality performance in a wide variety of operating conditions. We provide them with the most up-to-date tools needed to improve designs based on pollution control, savings and safety. Because of this, effective changes can be made quicker and communicated more efficiently.

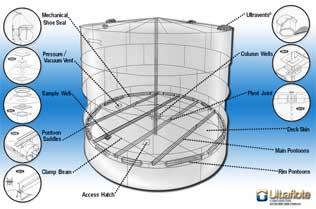

The following design features make our covers stand out as innovative and industry-defining.

Strength

Although designed to hold point loads of up to 750 pounds (340.2 kilograms) – which exceeds API standards by 50% – our roofs have been tested with over 2,000 pounds (12 workmen) concentrated on only one panel section.

Pontoons and Pontoon Saddles

Our aluminum alloy pontoons are 225% stronger than our closest competitor, and we pair these with 4” saddles capable of distributing clamp beam loads over 100°.

Pivot Joints

Pontoons are able to move in relation to one another with greater flexibility because we include pivot joints into the design eliminating end cap failures common to other designs.

Deck Skins

Our standard deck skins are 0.023” (0.5842 mm) thick, which is 27% thicker than the standards set by API. Because our panels are 102” [2,591mm] wide, they strengthen the roof while minimizing joints. Other thicknesses are also available.

Clamp Beams

The metal-to-metal joints included in Ultraflote Cover solutions are vapor-tight, balanced and symmetrical along both axes in order to maximize the clamping strength needed for an optimal design.

Structural Bolts

Self-tapping screws are out. We use high strength 3/8” stainless steel bolts for superior strength and long life.

All of Ultraflote’s internal floating roof solutions can be customized, or enhanced with the addition of one of our accessories designed specifically to meet your unique needs.

Ultravent® Peripheral Roof Vents

Aerodynamic, removable and rainproof, our peripheral roof vents, at a minimum of four per tank, bolster air circulation with 2 feet2 [0.2 meter2] of venting for every 10 feet [3 meters] of tank diameter. Bird screening is included. Our peripheral roof vents are installed near the edge of the tank and can double as inspection hatches.

Center Vents

The 8” [203mm] center vents, which come equipped with bird screening, exceed API standards and promote natural convection flow throughout the tank. In addition, a vent can double as a painter’s pin or scaffold hanger’s pin.

Overflow Vents

Complete with bird screening and a rain hood, these 6” x 48” vents are installed in the top of tank shells to manage the height of liquids and support better air circulation. These can replace one peripheral roof vent.

Fixed Roof Manways

Our manways are 36”square [914 mm], constructed of steel and installed on external fixed roofs to provide more expedient access. Lids are lockable, loose, hinged and also available with a thief hatch if desired.

Ground Cable Assembly

A minimum of 2 per tank are required. Ultraflote supplies 1/8” diameter stainless steel cables that prevent static charges by connecting the highly conductive floating cover to the fixed roof. The number required is a function of the diameter of the tank.

Anti-Rotation Assembly

A 1/4” diameter stainless steel cable is passed through a sealed fitting in the rim plate. To prevent rotation, the cables are attached vertically from the bottom to the top of the tank.

Seals

With over 30 different types of seals currently available in a wide variety of materials, we are able to provide anything you need to ensure compatibility. Some of our options include single, double, triple and quadruple wiper seals, metal shoe seals with and without secondary and metal and log liquid mount seals, also with and without secondary. Materials include our proven Ultraseal® I and Ultraseal® II flexible wiper seal elastomers, stainless steel shoes, and Teflon fabrics.